FEATURED PRODUCTS

TW

APPLICATION:

Used as interior house wiring at circuit voltage up to 600 Volts. Suitable for the type of service where conductor temperature does not exceed 60°C in dry or wet location

CONDUCTOR:

Solid or stranded soft drawn copper conductor.

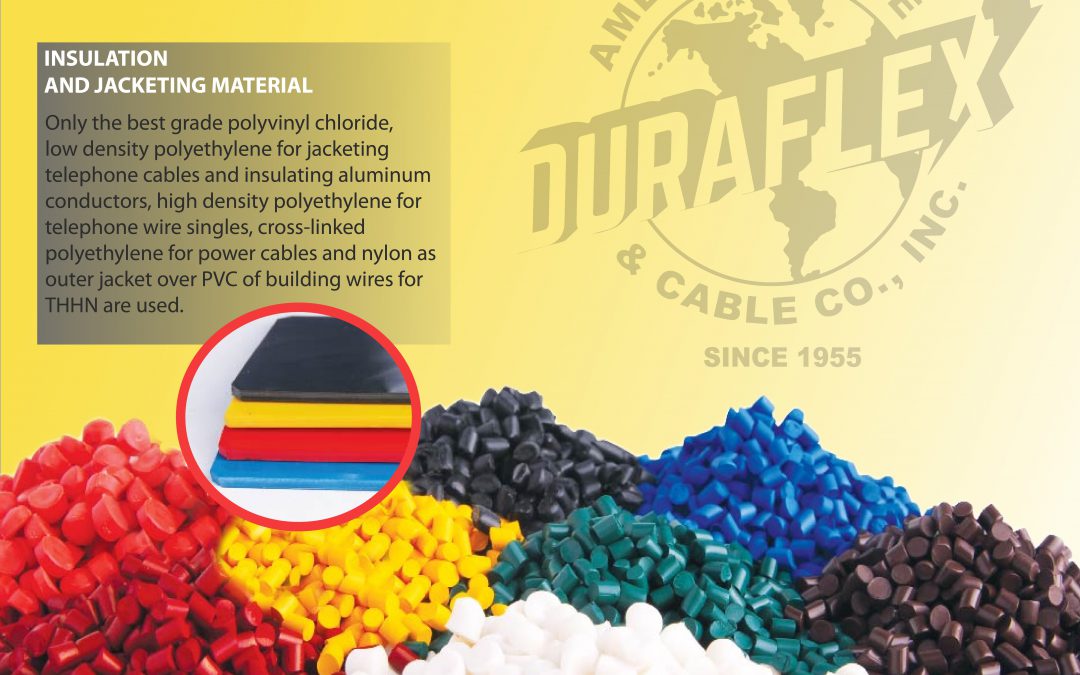

INSULATION:

Polyvinyl Chloride (PVC) Lead-free is flame retardant and resistant to moisture.

FEATURED PRODUCTS

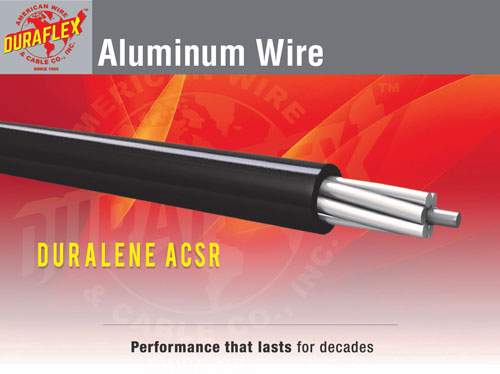

DURALENE AAC

APPLICATION:

Used as power transmission or distribution line. For multiflexed cable, it is used as uninsulated neutral support or messenger wire

CONDUCTOR

Stranded hard drawn Aluminum Conductor Reinforced ( ACSR ).

INSULATION

Black Polyethylene ( PE ) is resistant to acids, alkalies, water, salts, organic solvents and oxidizing compounds. Also, it is highly resistant to sunlight, abrasion and environmental impact.

FEATURED PRODUCTS

DURAPOWER 601 – 2000 V (XLPE)

Application

Used for circuits rated 600 Volts where installation is done in conduits, trays, troughs, underground ducts and aerial.

CONDUCTOR

One, two, three, or four stranded soft drawn copper conductors.

INSULATION

The individual conductor is extruded with Cross-Linked Polythylene (XLPE) for primary insulation, and Semi-Conductive Compound Copper Tape for insulation shielding (for shield type cable)

JACKET

Single or assembled multi-conductor cable is extruded with Polyvinyl Chloride (PVC) Lead Free for final protective covering.

FEATURED PRODUCTS

DURACORD

APPLICATION

Used as portable cable, emergency wire or inside building wiring in circuit not exceeding 300 Volts (0.75 mm² – 3.5 mm²) and 600 Volts (5.5 mm² – 30 mm²) respectively at maximum temperature rating of 60°C. Normally used in areas where high flexibility is required.

CONDUCTOR

Two, thee, or four soft drawn bunched/ropelay copper conductors.

INSULATION

Individual conductor is extruded with Polyvinyl Chloride (PVC) Lead Free color coded (for circuit identification). This thermoplastic is flame retardant and resistant to moisture.

JACKET

Assembled multi conductor cable is extruded with Black Polyvinyl Chloride (PVC) Lead Free for final protective covering.

FEATURED PRODUCTS

GUY GRIP

Used for the termination of steel strand guy used in the construction of distribution lines. They are rated at 100% of the strand’s published breaking strength.

About American Wire

and Cable Co., Inc.

For more than 68 years, AmWire has actively supported wire and cable requirements of local and multinational companies in the Philippines.

In these challenging times, the company’s strong commitment towards quality and timely service to its customers spurs AmWire to be a steadfast partner of essential industries in the country.

Organized in 1954 and incorporated in the Philippines in 1955, American Wire & Cable Co., Inc. is the pioneer in manufacturing wire and cable products at par with global standards in Quality, Safety, and Product Integrity.

AmWire founder Albert Awad envisioned this very first wire factory in the Philippines to locally manufacture electric wires to spread power throughout Manila and outlying small barrios.

Benchmarking its operations with international standards and employing competent Filipino experts, AmWire launched its full operations in 1956 and began integrating a series of product testing in its assembly line to ensure that each product passes the standards for quality, resilience, correct lengths and weights in its category. From its premium raw materials, cutting-edge manufacturing processes, and reliable product testing protocols, AmWire wires and cables have consistently complied with local and international standards.

Its flagship brand Duraflex, which symbolizes the company’ commitment to quality, has remained the brand of choice for the safest and most reliable wires and cables for electrical transmission and construction projects.

Wire & Cable Updates

AmWire’s Duraflex THHN/THWN UL83 rating conforms to US grade standards

The safety of our Customers is our first priority. That is why at American Wire & Cable, we ensure that our products are compliant to specifications of local and international standards. This includes the Duraflex THHN/THWN building wires, a locally manufactured...

Saving Cents on Wires & Cables? Choose Cost Effective Over Cheap!

What is the truth behind cheap and cost-effective wires and cables? Any supplier or hardware store clerk can say that they are all the same. With cheap alternatives in the market, it is understandable that end-users will just save a few pesos and buy these, without...

Not All Wires are the Same

Just about anyone can make cheap wire. It is easy to make it smaller in diameter, shorter in length; or use low cost scrap metal and low grade plastic. The challenge is to not compromise on quality but still remain competitive. At American Wire & Cable Co. Inc.,...